As seen in the Tried & True Spring 2023 issue

From natural resources drawn out of the earth to highly engineered drainage buried underground, the supply chain acts as the circle of life for products like Fratco pipe. Let’s take a closer look at how the system of global supply actually works, where it all began and why it might be changing in the not-so-distant future.

Source, Refine, Combine, Fulfill

In broad strokes, a supply chain consists of a few fundamental steps:

1. Sourcing Raw Materials

The unrefined resources needed for industry are extracted or harvested by organizations that specialize in the task.

Example: A company drilling for oil or mining for minerals

2. Refining those materials into parts

Raw materials are purchased by businesses that specialize in making components used by other businesses to manufacture products.

Example: A chemical company that synthesizes petroleum into different types of plastics

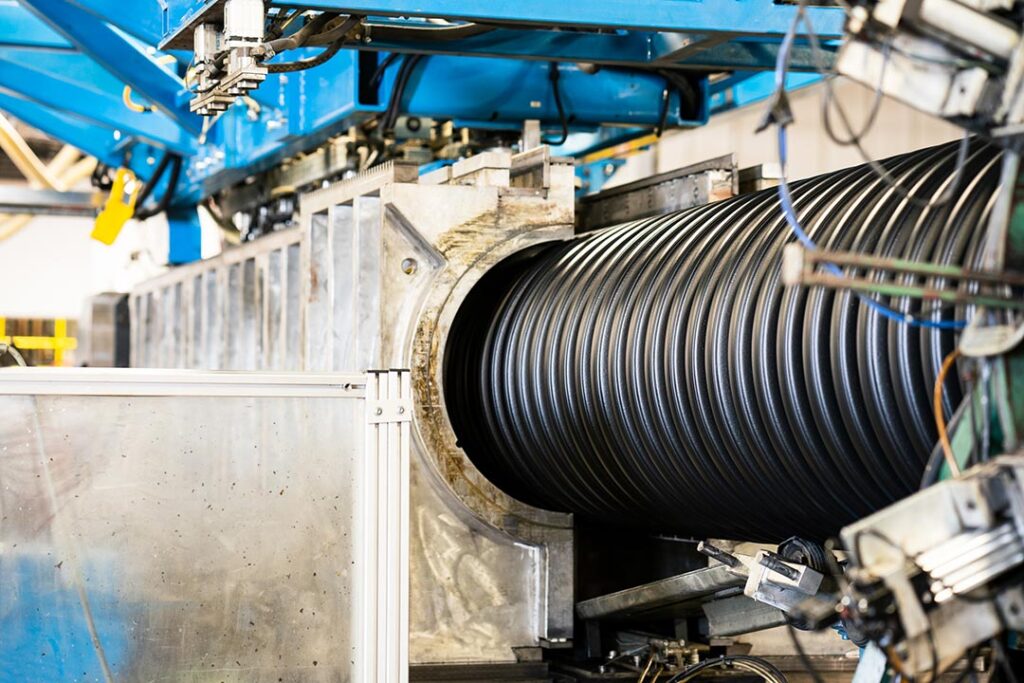

3. Combining those parts into products

Refined parts are purchased and assembled, combined, remolded or further processed into products for the market to be sold.

Example: Fratco making corrugated pipe from HDPE plastic

4. Fulfilling or delivering those products

Whether it’s the company themselves delivering their products to the customer, or a logistics company moving other businesses’ goods to retail outlets for purchase, this is where a newly-made product comes in contact with its new owner—or reseller—and the supply chain comes to an end.

Example: Fratco pipe transported on Fratco trucks to a distributor

Naturally, every link in the chain is connected by some method of transport: oil is moved to refineries via big rig or barge; freighters carry minerals in bulk across oceans; Coca-Cola trucks deliver refills to Mom and Pop’s drug store. Transportation infrastructure is the backbone of the supply chain, which is why Fratco is proud of the role its products are able to play in the construction of infrastructure itself. To learn more, check out the article entitled “Off the Farm” from the Fall 2022 issue of Tried & True.

Forging Today’s Global Supply Chain

Supply chains have been around for centuries in one form or another. Due to the dangers that came with traveling in the ancient world, however, mankind’s earliest supply chains were strictly local—the village farmer grew the wheat, the village baker bought it to turn into bread, and so on. If you lived during these times and your village happened to lack a “link” in the chain, you were simply out of luck (and bread).

As knowledge of the world progressed and traveling vast distances became more viable, regional trading networks like the Silk Road and the Spice Routes formed. These were used to transport goods between societies that were both geographically distant and culturally distinct from one another.

After the goods had been transported—usually by trading caravan or ship—workers and craftsmen in the nation of purchase would further refine their imported materials to suit their customers’ tastes—tastes that were often quite expensive, as was necessary to afford foreign goods. Today, the ornate togas of ancient Roman aristocrats and the intricate outfits of British royalty are considered emblematic of their civilizations, but neither garment would have been possible without imported Chinese silk. On the other side of that coin, much of the cuisine we have come to associate with certain regions—Chinese Pepper Steak, for example—relied heavily on spices and ingredients sourced from other nations. Looking back through history, it’s interesting to think how many things now considered staples of various cultures were actually the product of intercultural commerce.

Unfortunately, the earliest formation of a truly global supply chain likely dates back to the intercontinental slave trade that arose between North America, Africa and Europe during the 16th century. Slaves and the goods they produced were extremely profitable, and the promise of riches drove merchants to brave the immense risks and complex logistics required to maintain these more demanding trade networks with the limited technology at their disposal.

With the dawn of the Industrial Revolution in the 18th century, the global supply chain we know today really started to take shape. In North America and Britain, factories made mass-production possible just as railroads made transporting products a breeze compared to caravans of the past. Meanwhile, the adoption of steam-powered vessels made moving goods across the ocean more efficient than ever before. Later on, as more countries like China, India and Mexico industrialized, they too became essential links in the global supply chain—one that was quickly beginning to look more like a web.

This new system of supply and demand left little room for local preference. Now, if an American manufacturer wanted to match their competition’s prices, they couldn’t afford not to source their parts from countries where lax human rights laws meant reduced labor costs. Thankfully, consumers themselves eventually took a stand against these practices to great effect—particularly in the USA.

Today Fratco is proud that—in a century of doing business—the company has always operated with an all-american labor force alongside quality components that are ethically sourced.

Weak Links Revealed and Solutions Found

Before COVID swept the globe in 2020, many thought of the global supply chain as an efficient, well-oiled machine. Conditions brought on by the pandemic, however, revealed the supply chain to be far more fragile than even experts were aware. Due to facility shutdowns, labor shortages and infrastructural failures, many critical materials became limited or unavailable to manufacturers around the globe. The global resin shortage of past years—the ripples of which are still being felt—is a great example.

As a silver lining to the situation, the concept of supply chain resilience is now making the rounds among industry leaders with huge stakes in international commerce. In the USA, new local-sourcing and tech-driven initiatives are underway to fortify our corner of the global supply chain. Recent breakthroughs in artificial intelligence, in particular, hold the promise of a global supply chain that can predict its own disruptions and prevent a full-blown crisis.

Fratco leadership, too, has been taking action to strengthen their logistical operations. Recently, in the face of mounting gas prices, the company invested in a new fleet of smaller, more agile delivery trucks to lower fuel expenses that may have otherwise impacted customers. The idea is just one of many ways that Fratco approaches the future with a mindset of “adapt, evolve and thrive.”